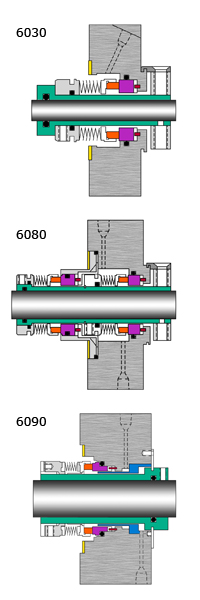

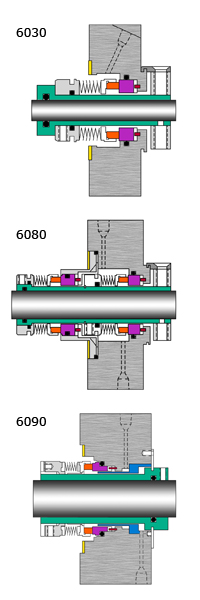

6030 Mechanical Seals & 6040 Mechanical Seals

The FSI 6030/6040 seal line is a hearty single cartridge rotating metal bellows seal, designed for handling even the toughest operating conditions in refineries, petrochemical plants, and chemical plants.

FEATURES:

- Inherently and hydraulically balanced

- Centralized face loading ensures even face loading (flatness) throughout all temperature and pressure ranges

- Tangential porting to maximize flush effectiveness

- All o-rings are static; no dynamic o-rings

- Rotating bellows design are self-cleaning, through rotational expulsion of particulates

- The 6040 is provided with quench and drain ports as standard. Options include restriction bushing, lip seal or die formed graphite ring containment system.

6080 Series Mechanical Seals

The FSI 6080 is a double cartridge rotary metal bellows seal, double balanced to provide both pressurized and non-pressurized seal operation. FSI 6080 seals are sturdy and versatile!

- Incorporates radial flow pumping ring for positive circulation All 0-rings are static; no dynamic 0-rings

- Two-piece gland allows for economical bi-metal construction Centralized face loading ensures even face loading (flatness) throughout all temperature and pressure ranges

- Available in all ANSI pump sizes for both standard bore and over size stuffing box configurations

6090 Mechanical Seals

The type 6090 seal is a heat-treated high temperature rotating metal bellows design. It is available as either a component seal or a cartridge mounted assembly. It has the same inherent features as our other metal bellows seals.

FEATURES:

- AM 350 SS or Inconel 718 bellows

- Graphoil secondary seals for high temperature service

- Flush, quench, and drain gland available with carbon or bronze restriction bushing

- Available steam purge bushing for hot hydrocarbons services

- Face materials of carbon, silicon carbide, and tungsten carbide.

OPERATION CAPABILITIES:

- Temperatures: 0°F to 750°F* (-20 C to 380 C)

- Pressures: Up to 300 psi* (20 Bar)

- Shaft Speeds: Up to 3600 RPM*

MATERIALS OF CONSTRUCTION:

- 6030, 6080, 6090 Mechanical seals incorporate AM350 SS and Inconel 718 as Standard materials.

- Our manufacturers can provide any combination of Carbon, Silicon Carbide, or Tungsten Carbide seal faces (appropriate for the pump/seal application).

- ASI offers standard O-ring material such as Fluoroelastomer, Perfluoroelastomer, Aflas, EPR/EPDM as standard. All other commercially available elastomers as specified.

- Type 6090 utilizes Graphoil secondary seals for high temperature applications.

- ASI can provide sizes ranging from 1.00 in to 5.00 in

- ASI can also provide the same range of sizes in metric measurements.

*As always, consult your ASI representative for applications which approach or exceed these parameters.