Simple, Robust, Proven

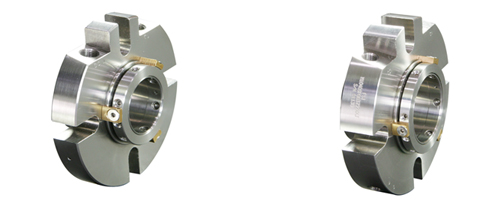

A single cartridge flexible stator design

The FSI Type 1030 is a simple, proven, robust design that makes up the foundation of the FSI product line. This single cartridge flexible stator design is perfect for industrial use with most ANSI and DIN pumps. This versatile design can be adapted for use in many other pumps and other rotating equipment. It is capable of handling the most demanding services and fits standard pump stuffing boxes without modification. It is also designed to fit big bore seal chambers.

The multi-spring stationary design of the FSI Type 1030 with its monolithic faces can compensate for misalignment between the pump housing and the rotating shaft. The springs and pins are located outside of the process to avoid clogging while the dynamic O-ring moves over a clean area as the stationary face wears, eliminating the potential for O-ring hang-up. The FSI 1030 is hydraulically balanced for cooler, longer running operation. The rotating face is shrouded in a stainless-steel carrier, virtually eliminating breakage under excessive conditions.

The FSI Type 1030 Cartridge is easy to install. The setting clips position the cartridge axially, concentrically and with proper perpendicularity to the equipment. The recessed gasket area eliminates the opportunity for extrusion and a large flush port is suitable for API plan 11, 13, or 32 operations. As with all our seals, the FSI Series 1015 is factory preset to eliminate installation errors and pressure tested to ensure greater sealing reliability for your application.

The FSI Type 1040 incorporates all of the design features and advantages of the Type 1030 and includes additional ports for quench and drain connections. In conjunction with the quench & drain ports, a close clearance throttle bushing is included. Options for other auxiliary restrictive devices include: customer designed lip seals, bronze labyrinth bushings and die formed packing.

OPERATING PARAMETERS:

Temperatures: 0F to 600F (300 C)*

Pressure: Up to 600 psi (40 BAR)*

Shaft speeds Up to 3600 RPM*

MATERIALS OF CONSTRUCTION:

Metal Components: 316 Stainless Steel**

Seal Face Materials: Carbon, Silicon Carbide, Tungsten Carbide

Elastomers: Fluoroelastomer (FKM), Perfluoroelastomer (FFKM), Aflas® (TFE/P), EPR/EPDM as standard O-ring materials. All other commercially available elastomers as specified.

Sizes: 1.125” (28mm) Up to 2.750” (70mm)

*As always, consult your ASI Representative for applications which approach or exceed these parameters. Thank you.

**Premium materials are available upon request